Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

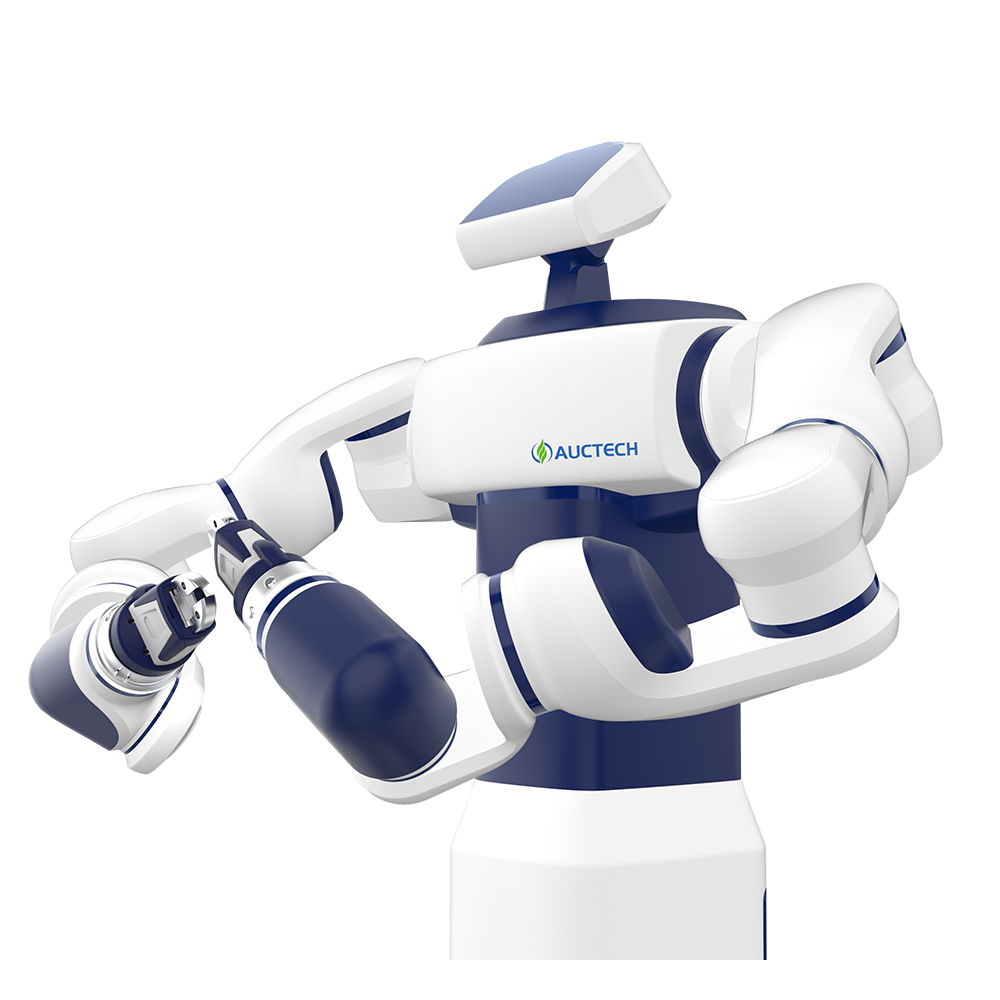

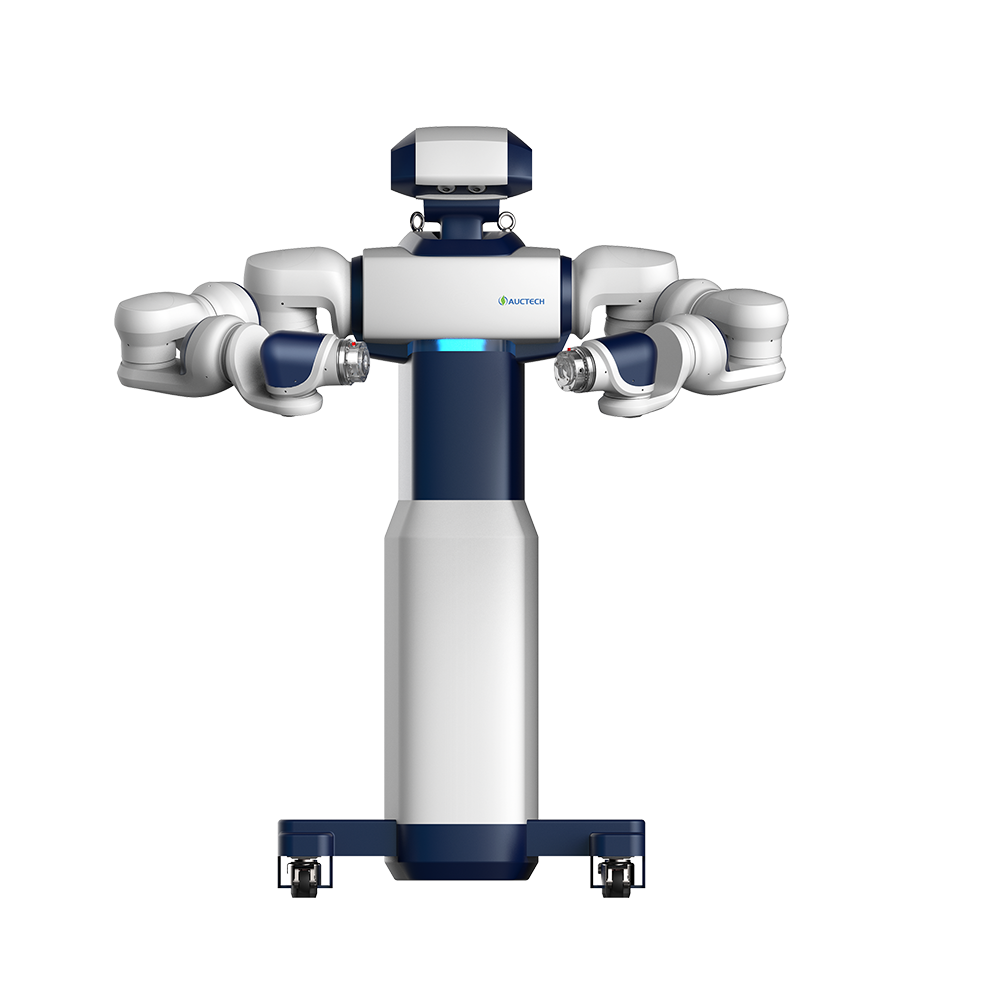

Enhance Precision and Efficiency with Dual-Arm Collaborative Robots (Cobots)

Imagine a manufacturing floor where two robotic arms work in perfect harmony alongside human operators—delicate enough to assemble intricate components yet powerful enough to handle heavy loads. This is no longer a vision of the future; it’s the reality brought to life by dual-arm collaborative robots. Combining advanced technology with intuitive operation, these cobots are redefining productivity and safety in industries ranging from electronics to automotive manufacturing.

What Are Dual-Arm Cobots?

Dual-arm cobots are next-generation robotic systems designed to mimic human movement and coordination. Unlike traditional single-arm robots, they feature two articulated arms that can work together or independently on complex tasks such as assembly, packaging, welding, or quality inspection. Built with built-in sensors and safety features, they operate safely alongside humans without the need for bulky safety cages.

Key Advantages of Dual-Arm Collaborative Robots

-

Human-Like Dexterity: With dual-arm robotic automation, tasks requiring precision and coordination—like threading wires or assembling small parts—can be automated effortlessly.

-

Flexibility: These adaptable industrial robots can be quickly reprogrammed for different tasks, making them ideal for high-mix, low-volume production lines.

-

Space Efficiency: Dual-arm cobots consolidate the functionality of two robots into a single system, saving valuable floor space.

-

Enhanced Safety: Equipped with force-limiting technology and collision detection, collaborative robotic arms ensure a safe working environment.

Applications of Dual-Arm Cobots

From precision assembly in electronics manufacturing to packaging in the food industry, dual-arm cobots are versatile performers. They excel in tasks such as:

-

Machine Tending: Loading/unloading CNC machines with precision.

-

Complex Assembly: Simultaneously handling multiple components in product assembly.

-

Quality Inspection: Using integrated vision systems to detect defects.

-

Laboratory Automation: Performing repetitive tasks in R&D settings.

Why Choose AUCTECH's Dual-Arm Cobots?

At AUCTECH, we engineer our dual-arm cobots to meet the evolving demands of modern manufacturing. Our robots are designed for ease of use, with intuitive programming interfaces that allow operators to train them quickly. With a focus on reliability, precision, and scalability, AUCTECH’s collaborative automation solutions help businesses boost productivity while reducing operational costs.

Have Questions or Want to Learn More?

Are you considering integrating dual-arm cobots into your workflow? Curious about implementation, customization, or ROI? We’re here to help! Share your questions or thoughts in the comments below, or contact the AUCTECH team directly for a personalized consultation. Let’s explore how dual-arm collaborative robots can transform your operations together.