Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

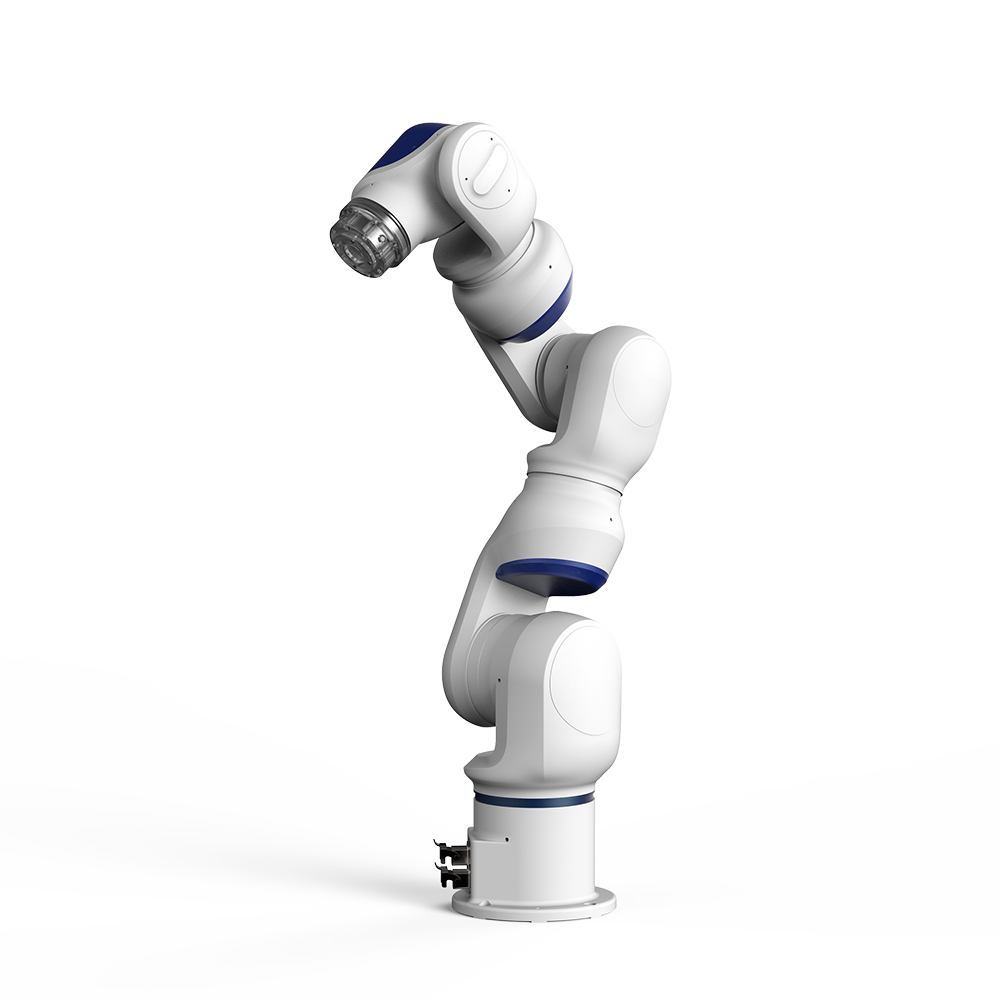

7-Axis Cobot Applications Unlocking Greater Flexibility in Automation

In modern manufacturing and logistics, space is limited, product variety is increasing, and production cycles are shorter than ever. Traditional robots with limited degrees of freedom often struggle to adapt to such dynamic environments. This is where the 7-axis cobot comes in. With its extended flexibility and human-like reach, it opens up new possibilities for industries that require precision, safety, and efficiency.

What Makes a 7-Axis Cobot Different?

A standard collaborative robot typically has six axes, which already allow for a wide range of motion. However, adding a seventh axis gives the cobot an extra degree of freedom that makes movements smoother and more natural—similar to a human arm rotating at the shoulder. This enhanced mobility enables the cobot to reach around obstacles, operate in tighter workspaces, and perform complex tasks that six-axis models find challenging.

Key Advantages of 7-Axis Cobots

-

Improved Reach and Flexibility: The additional axis allows the robot to move with greater dexterity, making it ideal for intricate assembly or confined spaces.

-

Human-Like Movements: A 7-axis cobot can mimic the natural motion of human workers, enabling safer collaboration and smoother integration into existing workflows.

-

Space-Saving Design: Factories with limited floor space benefit from the ability of these cobots to operate in tight and cluttered environments.

-

Enhanced Productivity: By taking over repetitive or ergonomically difficult tasks, they reduce worker fatigue while boosting efficiency.

Common 7-Axis Cobot Applications

The versatility of 7-axis collaborative robots allows them to be applied across a wide range of industries. Here are some of the most common and valuable uses:

1. Assembly and Manufacturing

In electronics, automotive, and consumer goods manufacturing, precision is key. 7-axis cobots for assembly can reach around obstacles, fasten screws, fit components, and handle delicate materials without damaging them. Their ability to work side-by-side with humans makes them perfect for hybrid assembly lines.

2. Welding and Fabrication

Welding tasks often require accessing difficult angles. A 7-axis welding cobot can rotate its joints in ways that ensure stable torch positioning, even in complex geometries. This reduces defects, improves weld quality, and minimizes the need for rework.

3. Machine Tending

Operating CNC machines or injection molding equipment often involves repetitive loading and unloading. A 7-axis cobot for machine tending can maneuver parts into tight spaces, improving efficiency and safety while freeing operators for higher-value tasks.

4. Logistics and Packaging

In warehouses and distribution centers, 7-axis cobots for packaging and palletizing excel at stacking boxes, labeling, and sorting goods in constrained spaces. Their extended flexibility allows them to adapt to varying product shapes and sizes.

5. Healthcare and Laboratory Automation

Beyond factories, 7-axis cobots in healthcare are used for lab testing, sample handling, and even surgical assistance. Their human-like motion and precision make them safe for sensitive environments.

6. Aerospace and Automotive Industries

These industries often require working inside confined spaces, such as aircraft fuselages or vehicle interiors. A 7-axis cobot can reach inside narrow spaces to perform drilling, fastening, and inspection tasks that are difficult for traditional robots.

Considerations Before Deploying a 7-Axis Cobot

While the benefits are clear, businesses should evaluate a few factors before implementation:

-

Task Complexity: Determine if the extra axis is necessary for the required applications.

-

Workspace Constraints: Smaller facilities may gain the most from the flexibility of a 7-axis cobot.

-

Safety Standards: Ensure compliance with international safety regulations for collaborative robots.

-

Integration Costs: Although cobots are easier to integrate than traditional robots, the advanced 7-axis models may require additional investment.

Future Outlook of 7-Axis Cobots

As industries continue to embrace flexible automation, the demand for 7-axis collaborative robots is expected to grow. With advances in artificial intelligence, vision systems, and adaptive software, these cobots will become even more capable—handling more delicate, complex, and human-like tasks.

Conclusion

The rise of the 7-axis cobot marks a new stage in collaborative robotics, offering businesses greater efficiency, adaptability, and safety. From manufacturing and logistics to healthcare and aerospace, their applications are diverse and rapidly expanding.

What do you think about the potential of 7-axis cobots in your industry? Would you like to explore specific use cases more deeply? Feel free to share your thoughts, ask questions, or get in touch—we’d love to hear your perspective.