Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

AWP-40L

The AWP-40L is part of AUCTECH’s advanced AWP Series of collaborative palletizing workstation solutions, engineered to deliver intelligence, safety, and operational ease for light industrial applications. Supporting payloads from 20 to 50 kg and a working radius of 1.48 to 1.98 meters with ±0.05mm high precision, the AWP-40L offers exceptional efficiency of 8-12 pieces per minute.

Compatible with vacuum grippers and mechanical claws, the AWP-40L easily handles boxes, sheets, bottles, and more. Its plug-and-play design, small footprint, and flexible scalability make it the ideal solution for intelligent, low-maintenance upgrades in industries such as food processing, pharmaceuticals, daily chemicals, and beverage manufacturing.

- Product Details

-

Download

Key Features

Easy Operation and Fast Deployment

The AWP-40L supports plug-and-play installation with a simple, intuitive commissioning process. Operators can quickly set up and deploy the system without the need for extensive training or complex programming.

Flexible Palletizing Memory Function

Thanks to its built-in memory function, the AWP-40L allows for flexible switching between palletizing schemes. This ensures efficient handling of multiple product lines and fast adaptation to production changes.

Compact Design for Flexible Layout

Featuring a small footprint, the AWP-40L fits easily into tight production spaces, enabling flexible site layouts and optimized workflow designs.

Simple Parameter Input and Pattern Selection

With straightforward parameter input and free selection of stacking patterns, the AWP-40L provides automatic alignment capabilities, streamlining the palletizing process for maximum accuracy and speed.

Reliable All-Day Operation

Engineered for 24/7 continuous operation, the AWP-40L significantly saves time, labor, and effort, making it an ideal choice for facilities seeking to improve overall productivity.

Broad Compatibility

The system is compatible with various types of boxes, sheets, and stacks, adapting seamlessly to different product specifications across a wide range of industries.

Enhanced Safety with Collision Prevention

Built-in mechanical collision prevention mechanisms ensure higher operational safety. The AWP-40L can also be equipped with optional safety accessories like guardrails or light curtains for additional protection.

Versatile Application Across Industries

The AWP-40L is widely used in multiple industries, including: food and beverage, household paper products, pharmaceuticals, daily chemicals, electronics, home appliances.

Automatic Lifting for High Stacking

Supporting automatic lifting up to 2.5 meters, the AWP-40L adapts dynamically to the palletizing height, enabling higher stacking and more efficient use of storage space.

Parameters

|

Model |

AWP-40L |

|

Weight |

Approx. 650 kg |

|

Payload |

40 kg |

|

Reach |

1980 mm |

|

Maximum Palletizing Cycle |

≤10 pcs/min |

|

Maximum Palletizing Height |

≤2650 mm |

|

Repeat Positioning Accuracy |

±0.05 mm |

|

Pallet Placement Form |

Manual, one left and one right |

|

Maximum Compatible Pallet |

1400 mm × 1200 mm |

|

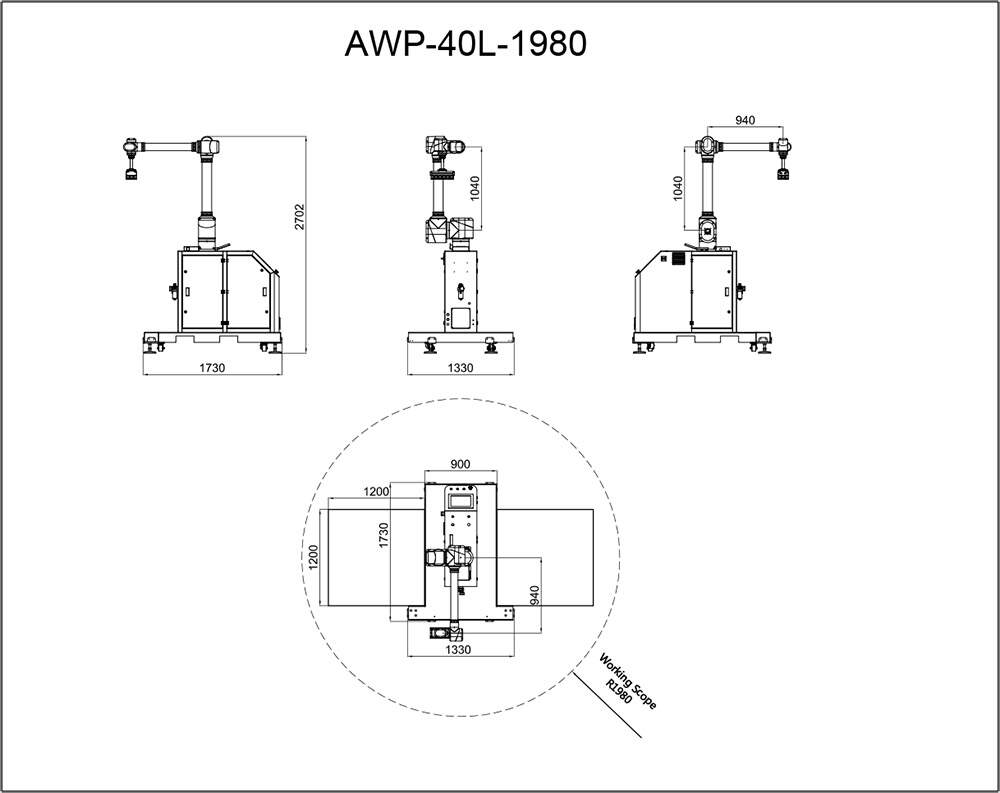

Dimensions |

L1330 mm × W1730 mm × H2702 mm |

|

Dimensions of Wooden Box |

L2250 mm × W1450 mm × H1900 mm |

|

Maximum Power |

3.5 kW |

|

Reference Gas Consumption |

240–460 L/min |

|

Power Supply Requirements |

AC 220V ±10%, 50Hz ±5% |

|

Gas Supply Requirements |

0.5–0.7 MPa |

|

Communication Method |

EtherCAT interface, expansion IO |

|

Protection Level |

Robot Arm IP53 / Cabinet IP24 |

|

Ambient Temperature |

0–50°C |

|

Noise |

<80 dB |

|

Main Color |

Blue Gray |

Dimension

Download

-

AWP Series Cobot Palletizing Workstation Catalog-V2.1.pdf